PVA TePla

PVA TePla AG is one of the world’s leading plant engineering companies. In December 2008, PVA TePla AG moved Headquarter to Wttenberg. At the same time the divisions of the company are restructured. The new divisions are now: Industrial Systems, Semiconductor Systems and Solar Systems.

PVA has a very good reputation around the world. Take Industry Systems for example, PVA TePla shares over 50% in the global market. In addition, PVA TePla has lots of experiences in the field of semiconductor business, which has become the foundation of the Solar Systems nowadays.

From now on, PVA TePla focuses more on crystal growing system. There are two major parts of the crystal growing system of PVA TePla. The first part is Crystal Growing System (CGS) GmbH which is located in Aßlar. As a spin off from Leybold Systems, it was founded in Hanau and now becomes part of PVA TePla in August 1999. The company was focusing on the construction of crystal growing systems for the semiconductor industry. The second part is floatzone system. PVA TePla took over floatzone crystal growing activities of the Danish company Haldor Topsoe in 2004, and now it becomes the leading brand in this field.

As we know, PVA TePla is the only company who can provide all the commercialized crystal growing systems, particularly for growing mono and multicrystalline silicon crystals. Also it is the only company who developed the first crystal growing puller which can grow 18 inches ingot, and the smallest crystal growing system in the world. The multiple design has showed the essence of highly respect for our customers. We keep designing high quality of automatic and customized crystal growing systems. This is our duty and our vantages.

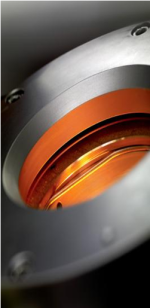

There are a lot of advantages in PVA TePla’s furnace. The most important part is that it uses interchangeable parts which can be update easily and immediately. Also, the company chooses to adopt digital signal communication to all the furnaces, which can simplified the production of the furnace and enhance the stability. When it comes to CoO, PVA TePla has a lot of solution to reduce the cost of production. One of the solutions is the argon recycling system which can recycle over 80% argon and reuse it. In addition, the unique design of the hot zone also can reduce the cost. What’s more, the feeder, the power consumption, and the friendly control panel are all under certain consideration which makes them unique and useful. That is the main reason why PVA TePla becomes the leading brand in the global market.